After the arduous long journey, waiting for the vibrational motors to arrive at Monash University, toiling with Ray in finding a new supplier after the old one took a MONTH to tell us they weren't sending them, we FINALLY got some vibrational motors!

Little Bird Electronics were a little more expensive, but they were able to ship within a day! Next time we'll have to look a bit harder and care a little less about price I think!

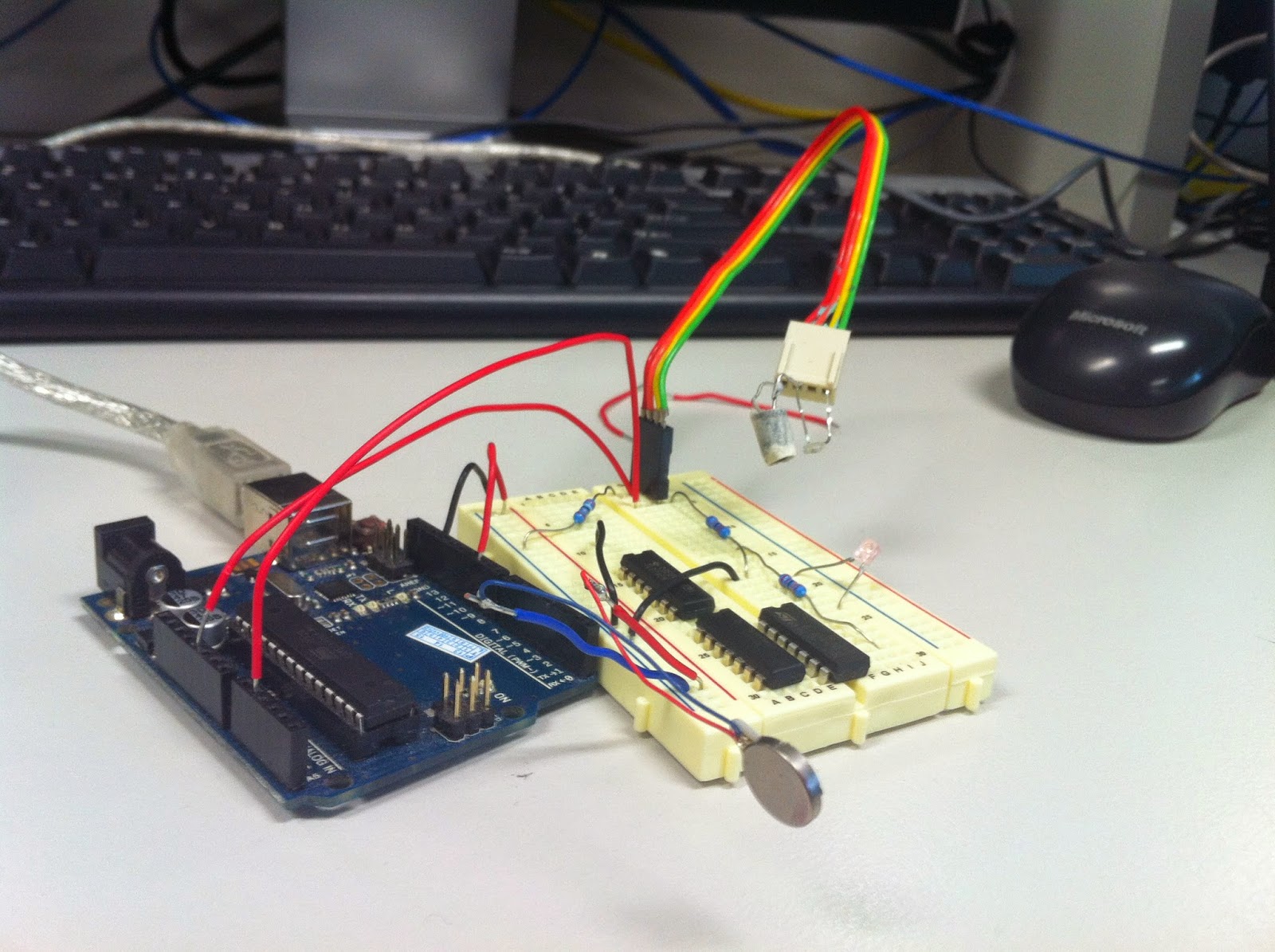

Here below, we have some of the first, ugly prototypes of the haptic feedback system working. The first figure is the ramshackle IR sensor for proximity (which will probably change), and the second is the motor in action! Or as 'in action' as can be seen in a stationary picture.

See below the whole set up. The IC's aren't actually part of the breadboarding, they're just...there. This set up was able to give graded haptic feedback at distances of 3cm from the lab table. The main problem is, again, the reflectivity of surfaces and how IR light is reflected. On different materials and different colours, the sensor feedback is different, and currently, requires a manual calibration to get meaningful graded feedback. I will be looking into ways to automatically calibrate the IR sensor, or possibly just use an series of high-power LEDs to illuminate objects.

Verifying that the prototype was functional, I made sure to create the motors as they would be on the glove when I procure one. As you can see below, it looks like the tendons of a hand, or maybe the nervous system you'd expect on a hand! (totally unintentional) Thanks must be given to Ray as to the connectors for the Veroboard :)

The next things to do will be, after the hand issue is sorted out, mounting the motors on a glove, and mounting the proximity sensors on another. Here's hoping for greater progress!

No comments:

Post a Comment